TURNING TECHNOLOGY

INTO OPERATIONAL EFFICIENCY

CATEGORY:

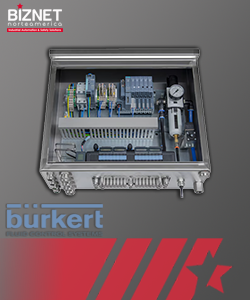

• Safety-related shut-off of valves possible

• Higher plant availability with PROFINET S2 (system redundancy)

• Process reliability through pneumatic functions

• Optimized for installation at the bottom of the control cabinet

• EX-Versions: ATEX / IECEx Zone 2, cURus Haz. Loc. CL I, II, III Div 2

• Optimised cleaning can be achieved due to HD stainless steel housings (Hygienic Design) according to protection class IP65. Available in three widths, each with the same height and depth dimensions

• Four different Bürkert valve island types, available with up to 40 valve positions and 64 valve functions

• Lower material requirements and installation costs due to close-to-process placement in hygiene-critical areas

• Optional assemblies, such as pressure monitoring, power supply unit, wall spacer, available

• High process reliability through P shutoff, check valves (R+S) and safety-related shutdown